TruLife Acrylic: What It Is, How It Works, and When to Use It

TruLife Acrylic is a premium art display acrylic offering significantly reduced glare while maintaining glossy surface. Comparable anti-glare performance could only be achieved before though etched surface. This article explains the correct use of the product, its limitations, and when it makes sense to pay extra for an upgrade.

What Is TruLife Acrylic?

TruLife Acrylic is a specialty acrylic sheet with a single-side reflection control coating specifically designed for face-mount applications. It is considered by many a Gold Standard in acrylic face-mount photo presentation and there is some merit in this statement.

TruLife Acrylic vs Regular Acrylic in Face-Mount Applications

For art buyers and galleries, TruLife Acrylic should be looked at as a performance upgrade rather than a universal solution. While offering significantly reduced glare TruLife Acrylic remains a high-gloss material. It does not eliminate reflections from strong light sources. Prints installed directly opposite large windows, skylights, or intense spot lighting will still exhibit visible glare. This behavior is inherent to glossy acrylic surfaces and should be considered during planning and placement.

Original limited-edition print by Alex Gubski mounted on TruLife acrylic

The primary advantage of TruLife Acrylic lies in its ability to suppress secondary reflections. Room elements such as lightly colored walls, flooring, furniture, and viewers themselves become significantly less visible on the print surface. This improves image legibility and viewer focus in most mixed-light interiors, including lobbies, corporate offices, hospitality spaces, and gallery floors with variable ambient light. Below is an example of a good candidate room for reflection control acrylic such as TruLife.

Bright Room appropriate for use of Trulife Acrylic

In controlled lighting environments, the functional difference between TruLife Acrylic and standard acrylic face-mounting narrows. When glare sources remain predictable and minimal, regular acrylic delivers excellent clarity at a lower material cost. For these installations, standard acrylic often represents a more cost-effective choice without compromising presentation quality. Below is an example of an interior for which use of TruLife would be a complete waste of money.

Dark room with regular gallery acrylic art on the wall

Galleries and commercial clients achieve the best results when material selection aligns with lighting conditions, viewing angles, and budget constraints. TruLife Acrylic provides measurable visual benefits in challenging lighting environments, while regular acrylic remains a practical solution for controlled display settings.

Correct Applications for TruLife Acrylic

TruLife Acrylic performs best in two applications only:

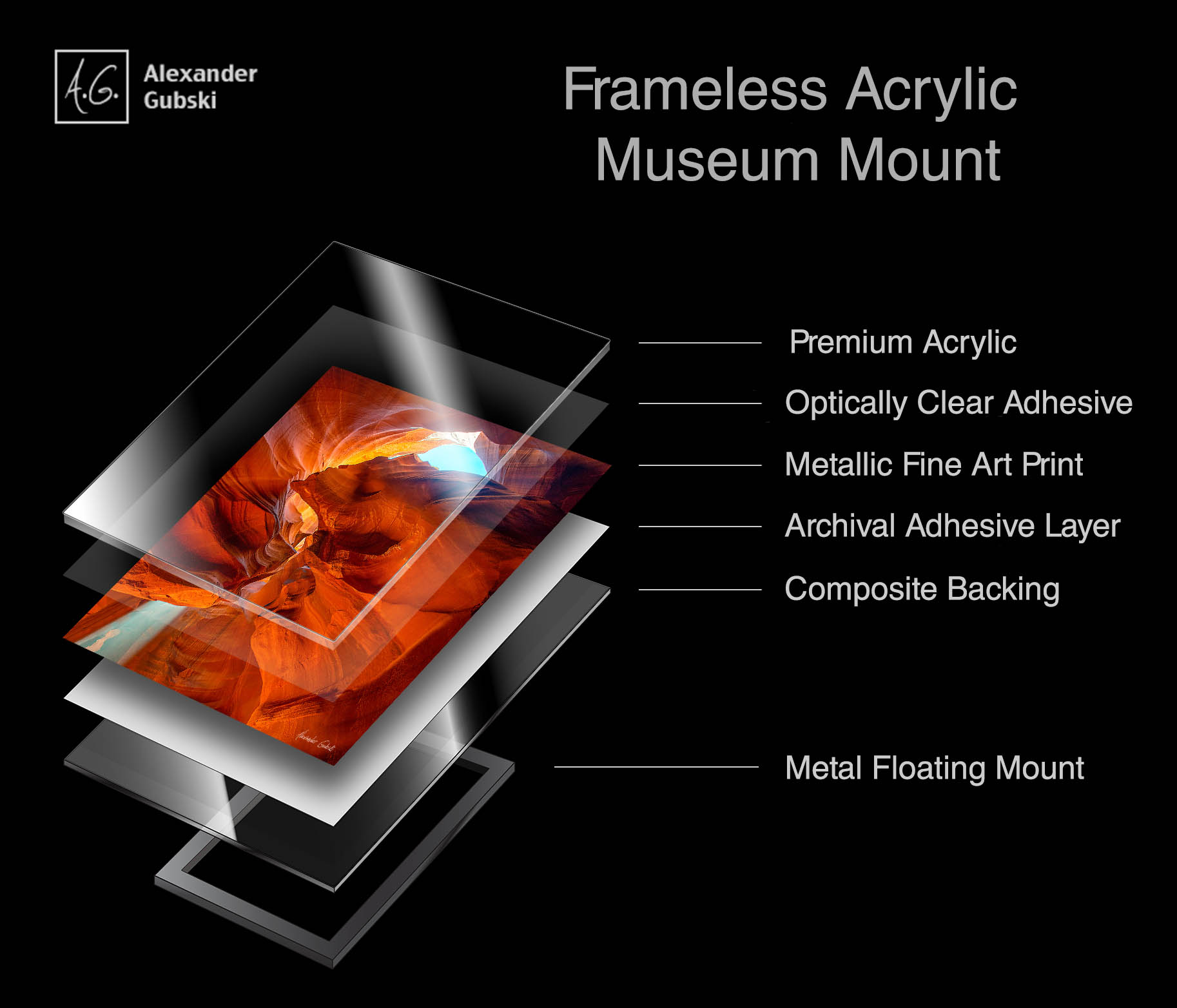

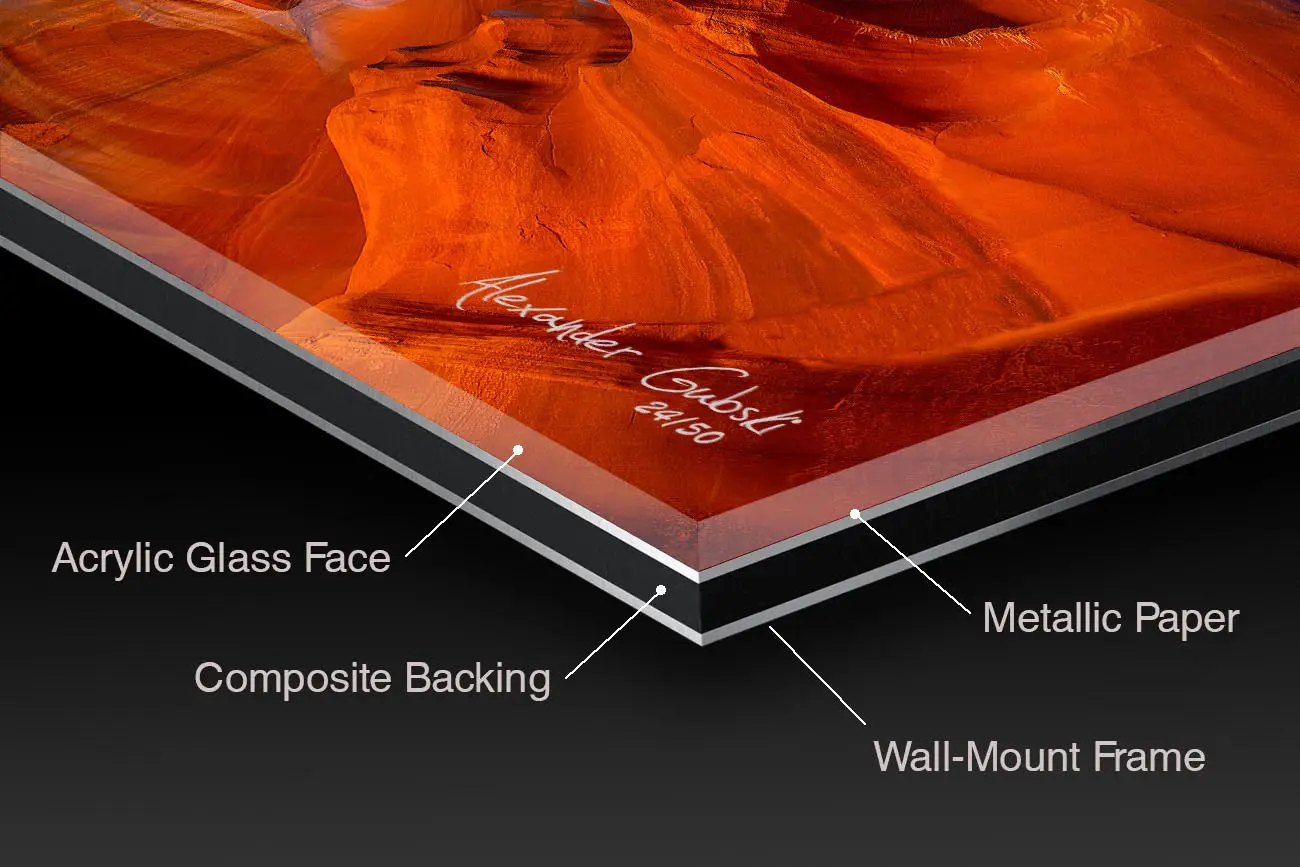

1. Acrylic Face-Mounting

In face-mounting, the print bonds directly to the acrylic surface. The un-coated side faces the image.

This creates strong depth perception, minimal reflections, vivid color saturation and a clean, modern look. Face-mounting is the most common professional use of this product.

2. Direct Printing on Acrylic

Some flatbed printers can print directly onto acrylic sheets. When done properly, TruLife Acrylic can serve as the print surface.

This method works because the ink bonds to the un-coated side, the viewing surface remains optimized and no air gap exists.

Cleaning Practices

TruLife Acrylic offers additional level of abrasion resistance compared to regular acrylic but still requires careful cleaning to protect its reflection control coating. The surface resists everyday dust, but improper cleaning can cause permanent damage. Always start by removing loose particles with a clean microfiber cloth. Never wipe a dry, dusty surface aggressively. This can create fine scratches.

Use cleaners designed specifically for acrylic. Spray the cleaner onto the cloth, not directly onto the acrylic surface. Gentle pressure works best. Let the cloth glide across the surface instead of pressing down. Avoid circular scrubbing motions that can stress the coating.

Never use ammonia-based or alcohol-based cleaners. These products can affect the reflection control layer. Household glass cleaners can permanently cloud the surface. Paper towels and rough fabrics also pose a risk. They may look soft, but they contain fibers that scratch acrylic.

Fingerprints should be removed as soon as possible. Oils can bond to the coating if left too long. Regular light cleaning keeps it clear and streak-free. When handled and cleaned correctly, the surface maintains its optical performance and premium appearance for many years.

Is it worth extra cost to upgrade to TruLife?

TruLife Acrylic is a great material when used for appropriate application. Check if your room gas a lot of bright objects that can reflect in the acrylic surface. See if you can mediate that glare using accent lighting and changing overall room lighting scene. If these measures are not successful or you just want to have the absolute best on the market, then invest into TruLife acrylic.

You can order any of my prints in either gallery acrylic or upgraded to TruLife if your display location has problematic

👉 https://alexgubski.com/gallery